David Mowatt, Chairman

Smoke Control Association (SCA)

David Mowatt, Chairman

Smoke Control Association (SCA)

David Mowatt, Chairman of the Smoke Control Association (SCA), offers guidance on maintaining these life safety systems and examines the wider framework shaping smoke control system maintenance today.

In the event of a fire, smoke often presents the most immediate danger to life due to asphyxiation, obscuring escape routes and the hampering rescue efforts. Well-designed smoke control systems are critical life safety features that can create and maintain smoke-free escape routes, assist firefighting operations and delay flashover. In doing so, the impact to life and damage to property is minimised.

Poor upkeep, however, has been a recurrent factor in building fire safety failures, leaving occupants exposed and duty holders vulnerable to prosecution.

The Regulatory Reform (Fire Safety) Order 2005 remains the cornerstone of fire safety obligations in England and Wales. It requires that facilities, equipment, and devices are subject to “a suitable system of maintenance” and kept in efficient working order. Non-compliance can lead not only to enforcement notices but also to criminal liability.

The Building Safety Act 2022 has further raised the stakes, particularly for higher-risk residential buildings (HRBs). Each HRB must have a Principal Accountable Person (PAP) with clear legal duties to manage safety risks. This includes ensuring smoke control assets remain fit for purpose.

Since January 2023, the Fire Safety (England) Regulations 2022 have required responsible persons to supply electronic and paper plans to the fire and rescue service, and to report any faults that cannot be fixed within 24 hours. These measures reflect a crucial reality: without clear building information and reliable systems, incident commanders are unable to make fast, informed decisions in an emergency.

In practice, these overlapping duties create significant challenges. Many buildings still lack accurate fire safety asset records, making compliance and effective maintenance harder to achieve.

Smoke control systems consist of a variety of components and vary in system type, each with distinct operational principles and maintenance demands.

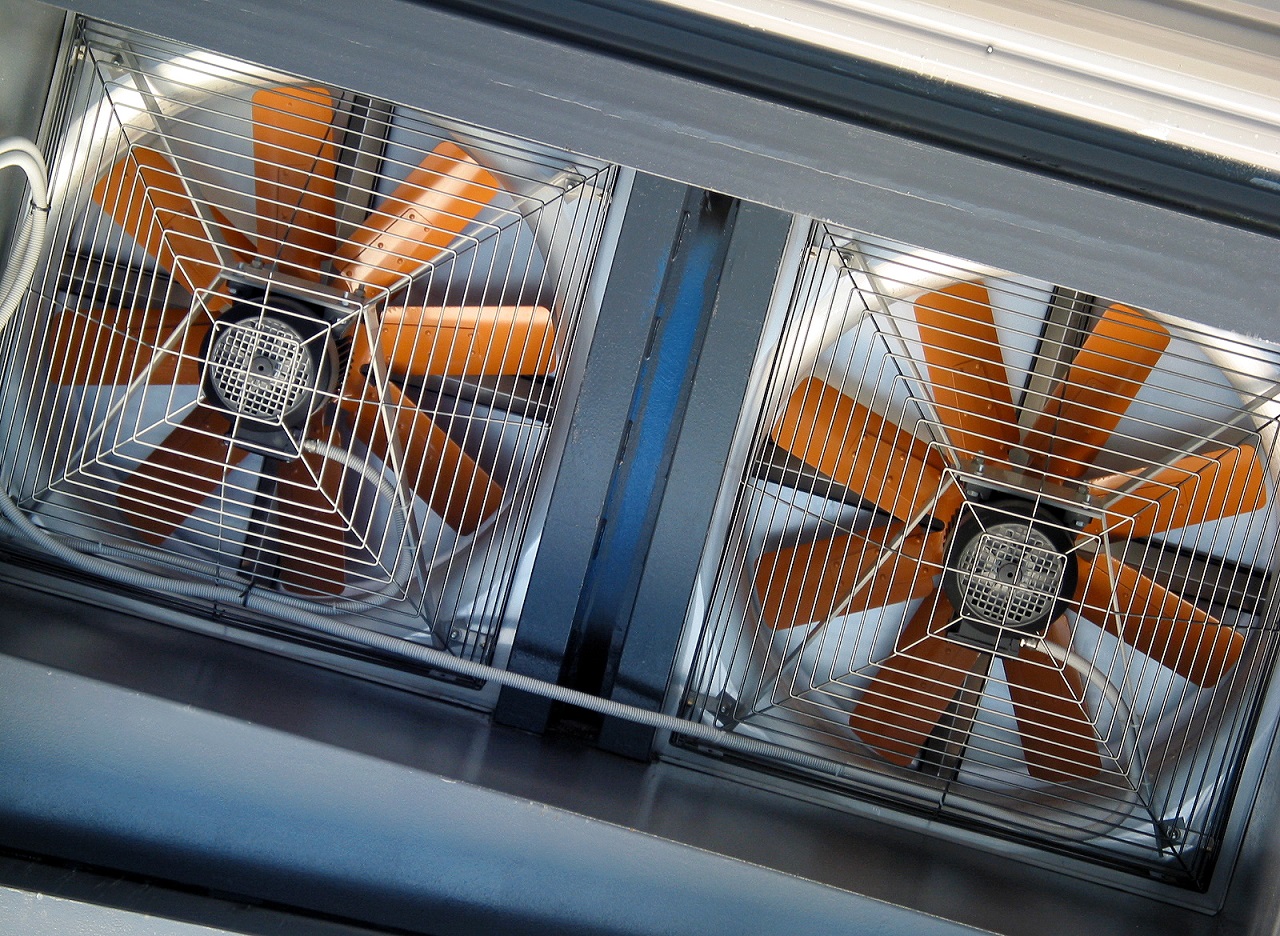

Each system comprises assets such as automatic opening vents (AOVs), smoke control dampers, control panels, actuators, fans, and power supplies. The essential performance characteristics, such as airflow rates, must be recorded and verified against the original system specific design data.

The latest SCA guidance distinguishes between new installations, where the Building Safety Act requires information to be provided to the responsible person as part of the Golden Thread of safety data, and existing installations, where records may be missing.

In such cases, duty holders must carry out physical inspections to build an asset register from scratch, identifying system components, manufacturers, and functions.

This register underpins all subsequent maintenance, inspection, and risk assessment activities and aids an understanding of essential fire safety assets. For mechanical systems, if the original performance design criteria are unavailable, additional design work will likely be required to verify specific performance requirements.

The terminology around responsibilities can be confusing. Under the Building Safety Act, the terms ‘Accountable Person’ and ‘Principal Accountable Person,’ together with the ‘Responsible Person’ under the Fire Safety Order, all designate the individual who holds the overall legal duty for maintaining a building and its fire safety systems.

Further maintenance roles include:

The Responsible Person should provide the Competent Maintainer with a full suite of information surrounding the system at the point of entering a maintenance agreement. The information will include design reference documents including the drawings, cause and effect, flow rates requirements for mechanical systems, and the building’s fire strategy document. Additionally, the Responsible Person will provide a record for all known system issues and non-conformities. This is so the Competent Maintainer can check system performance and functionality against original system specification.

Upon acquiring or taking over a building, it is critical to implement a maintenance regime that satisfies the requirements of all relevant regulation and standards. Crucially, BS 7346-8 emphasises that maintenance, testing and inspections should be carried out against a defined performance requirement.

The Responsible Person should begin by securing all necessary documentation, including system design, installation and maintenance records, to understand the system’s specifications, performance criteria and current condition.

In accordance with BS 7346-8, if no suitable records are available, a system design performance requirement should be established or agreed. This may require an inspection of the system to obtain any critical building information needed for the design process.

The Responsible Person should then conduct or acquire a current Fire Risk Assessment to verify the system’s effectiveness and regulatory compliance.

The Responsible Person should maintain detailed records of these actions for future reference and compliance, creating a comprehensive framework to support the system’s ongoing management and safety.

The latest SCA guidance sets out minimum inspection intervals for mechanical, natural, pressure differential and mechanical car park systems, all of which should be subject to daily, weekly, monthly, three-monthly, six-monthly and annual checks. The annual maintenance check should be carried out by a certified organisation and frequency should always be increased where risk levels demand.

Each system type has specific maintenance variants, but the principle is consistent: regular, escalating checks moving from simple observation to comprehensive performance testing.

Accurate record keeping is vital. Records produced and presented by the Competent Maintainer should include, at a minimum:

All testing at each interval should be recorded in the site’s system logbook. This should include:

For higher-risk residential buildings (residential building over 18m in height), any unrectified fault must be reported to the fire service within 24 hours. Poor maintenance practices can invalidate insurance and undermine the credibility of any safety cases presented to regulators.

Smoke control systems do not operate in isolation, so interfaces with fire alarms, sprinklers, access control, and other building services should always be considered.

Joint annual inspections with other maintenance providers are recommended in order to verify correct integration. Temporary safety measures that may be put in place when systems are offline for maintenance or repair should also be risk-assessed and documented.

The evolution of legislation and the heightened scrutiny of building safety are reshaping expectations, with increasing emphasis on competence, certification, and digital record-keeping intensifying.

For building owners and managers, this represents both a challenge and an opportunity – a challenge to improve practices, but also an opportunity to demonstrate leadership in safety and compliance.

Smoke control systems are among the most critical life safety measures in modern buildings. Their ability to preserve escape routes, support firefighters and protect assets is well-established, yet their reliability cannot be taken for granted.

The statutory framework demands continuous diligence, and SCA guidance provides a structured pathway to compliance: maintaining building asset registers, appointing competent personnel, adhering to inspection schedules, and maintaining robust documentation.

Maintaining smoke control equipment can be the difference between a system that performs when lives depend on it and one that fails when needed most.

For industry professionals, the message is clear – never cut corners when it comes to maintaining life safety equipment.