Stephen Benton

British Refrigeration Association (BRA)

Understanding the Pressure Equipment Directive

Stephen Benton of BRA explains two important regulations and highlights factors to consider during design and installation of pressure systems to help achieve compliance.

The EU Pressure Equipment Directive (PED)is one of many EU directives. They lay down basic rules for construction to ensure a consistent level of safety and to enable free trade. Compliance is demonstrated by a CE mark, backed up by a Declaration of Conformity.

Directives are transposed into national regulations; in the case of the PED this is the Pressure Equipment (Safety) Regulation (PE(S)R) in the UK. The PED has been in place since 2002, and post Brexit we still comply with it because it is a UK regulation (and because it is a practical way of ensuring pressure systems are safe).

Technically the PED and PE(S)R are identical, but there are some minor differences. These don’t affect the design of the system but they might impact how you demonstrate compliance. This article refers to PED for simplicity, but everything applies equally to the PE(S)R.

The PED, like other directives, is not a design guide. It lays down basic rules and lists essential safety requirements. However, to make things simpler, there are European standards (such as EN 378-2) which are harmonised with the PED. Following the specified clauses in the standards meets the relevant essential safety requirements. For example, strength testing a system to EN 378-2, clause 6.3.2 (Strength pressure test) meets the PED essential safety requirement for a proof test.

Why does the PED apply to installing contractors?

The PED applies to any system that runs at a pressure of more than 0.5 bar g, with a few exceptions which are not relevant to us. So, it applies to RACHP systems. It applies to systems when they are first put on the market – so it is for new systems, not existing systems (unless an important change is made).

Manufacturers of RACHP systems must demonstrate compliance with the PED. If you are installing a site-built or connected system, then you are classed as the ‘manufacturer’ of that system.

If you are installing a system in the EU (e.g. in Ireland) or in Northern Ireland it must comply with the PED, be CE marked and be assessed by a notified body (in Northern Ireland a UKNI mark can be used). A notified body is a third-party organisation authorised by an accreditation organisation in the EU.

If you are installing a system in Great Britain (England, Scotland and Wales) it must comply with the PE(S)R but can be either UKCA or CE marked and therefore be assessed by an Approved Body or a Notified Body.

A summary of the compliance procedure is as follows:

1. Classify the system

Determine the PED category of each component and the complete system, based on refrigerant type, maximum allowable pressure (PS), and volume or pipe size

2. Involve a Notified/Approved Body (if required)

Required for Category II, III, or IV systems, they will review your technical documentation and may need to witness strength testing

3. Prepare technical documentation

Include system drawings, pressure ratings, risk assessment, and qualifications. Show how the design complies with the essential safety requirements, typically by following relevant harmonised or designated standards

4. Strength test the system

Test at the correct pressure; some tests must be witnessed depending on the category

5. Mark and certify

Apply CE or UKCA mark and issue a Declaration of Conformity

Hazard categories and how systems are assessed

Individual components in the system and the complete system have a hazard category. This is determined from the type of component (piping, vessel, pressure accessory or safety accessory), the refrigerant, maximum allowable pressure (PS) and size. In essence things which are bigger and/or have greater PS and/or run on a more dangerous refrigerant have a higher hazard category.

There are five categories, I to IV are formal hazard categories:

- SEP – sound engineering practice. Items and systems do not need to meet the PED’s essential safety requirements and are not CE or UKCA marked

- Category I. Items and systems must meet the essential safety requirements, are CE or UKCA marked but are self-certified

- Categories II, III and IV must meet the essential safety requirements, are CE or UKCA marked and are assessed by a notified or approved body

The notified or approved body assessment is more onerous the higher the hazard category. For example, for systems which are hazard category IV the notified/approved body will usually need to witness all strength testing.

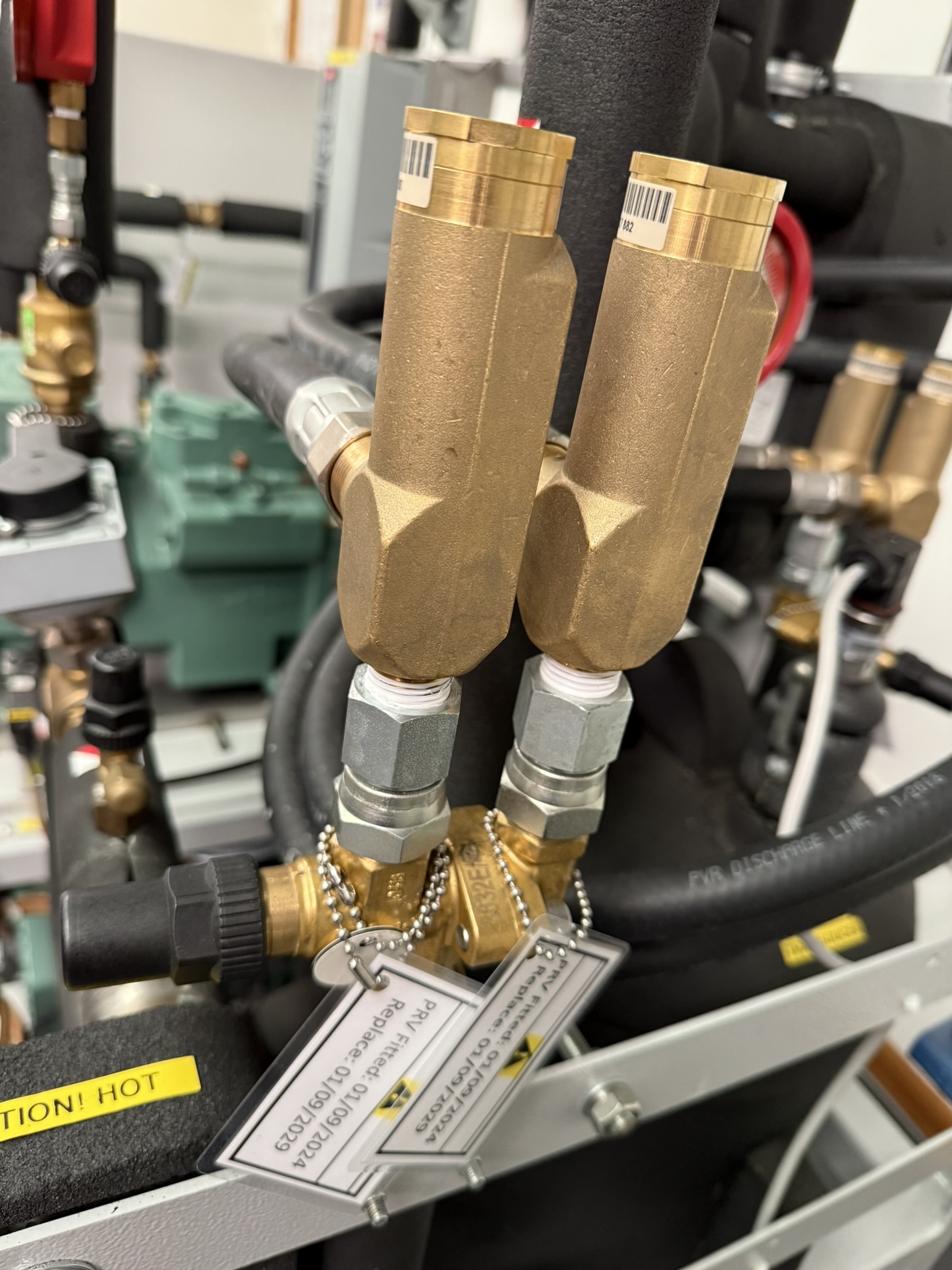

The hazard category of the complete system is simply the highest individual hazard category, ignoring safety accessories such as PRVs which are always category IV.

Installing contractors need to be aware of the system hazard category but also the category of all the joints on the system (pipe to pipe and pipe to component):

- Joints which are SEP or category I can be brazed by brazers with an industry standard brazing qualification (e.g. the BRA scheme) and are pressure tested at 1.1 x PS.

- Joints which are Category II or higher must be brazed by brazers with a qualification from a notified / approved body and must be pressure tested at 1.43 x PS (or 1.1 x PS with 10% non-destructive testing).

Most joints are SEP or category I, but larger R744 systems and many systems using flammable refrigerants (e.g. A2Ls) have joints which are category II or higher.

Risk analysis and essential safety requirements

A risk analysis must be carried out identifying hazards associated with pressure and showing how they are eliminated or reduced and what protection methods are used. The essential safety requirements listed in the PED form the basis of this risk analysis. Most of the risks which are relevant to RACHP systems are met through compliance with harmonised standards.

The most important elements of the risk analysis cover:

- Determination of PS

- Selection of appropriate over pressure protection

- The use of components and assemblies which are rated for the relevant PS and, where required, are CE or UKCA marked in accordance with the PED

- The design of interconnecting pipe work – including the pipe OD and thickness, its routing and support

- Mounting of components, assemblies and pipe work to minimise vibration

- The brazing or welding of connections, either pipe to pipe or pipe to component

- Strength testing of the installed pipe work

- Protection of personnel from hot surfaces and PRV vents

Demonstrating compliance

Compliance with the PED is usually demonstrated by design and technical files (technical documentation). These primarily comprise the following information:

Design file:

- General description of the system

- Design information, including PS and hazard category for the individual items of pressure equipment and for the whole system

- Pipe size calculations, specifically to show gauge (thickness) is adequate

- The risk analysis

- Pipe layout drawing as installed

- PRV calculations (including for any vent lines fitted)

Technical file:

- Material certificates (e.g. for pipe and brazer consumables) and declarations of conformity for the items of pressure equipment in the system

- List of brazers/welders, their qualifications and procedures

- Strength test procedure and the certificate for the tests carried out

- O&M manual

- Draft declaration of conformity and CE plate for the completed system

These are submitted to the notified / approved body for category II, III and IV systems several weeks before the system is to be pressure tested.

Before the system is installed it is important that you:

- Check brazers/welders have the appropriate qualifications

- That all items are rated for your system PS (or higher) and that the over pressure protection prevents the system exceeding PS

- That you have all certificates and declarations (i.e. that all items meet the requirements of the PED)

- That you own and have read the relevant standards

- That you pressure test the system safely and to the correct pressures

Summary

The PED is a legal requirement in the UK under the PE(S)R. It is there to ensure pressure systems are safe and in the 23 years since its introduction has led to more consistent design and improved installation practices.

The result is safe, more reliable systems with reduced leakage, and of course, compliance with the law.

In this short article it is not possible to provide all the information you need to install PED compliant systems and to demonstrate compliance – contact the BRA if you need further information.