ACSEU LTD

ACSEU

Grease Management with Grease Trap

In every commercial kitchen, managing fats, oils, and grease (FOG) is essential for keeping operations efficient and environmentally responsible. When poorly managed, FOG can solidify in pipework, leading to blockages, foul odours, and costly repairs—issues that can easily spill into the public drainage system.

That is why an effective grease management strategy, supported by properly sized and maintained grease traps, is now a legal and environmental necessity for foodservice operators across the UK.

ACSEU Limited provides professional grease trap services throughout the UK, helping commercial kitchens stay compliant and avoid costly downtime.

What Is a Grease Trap and How Does It Work?

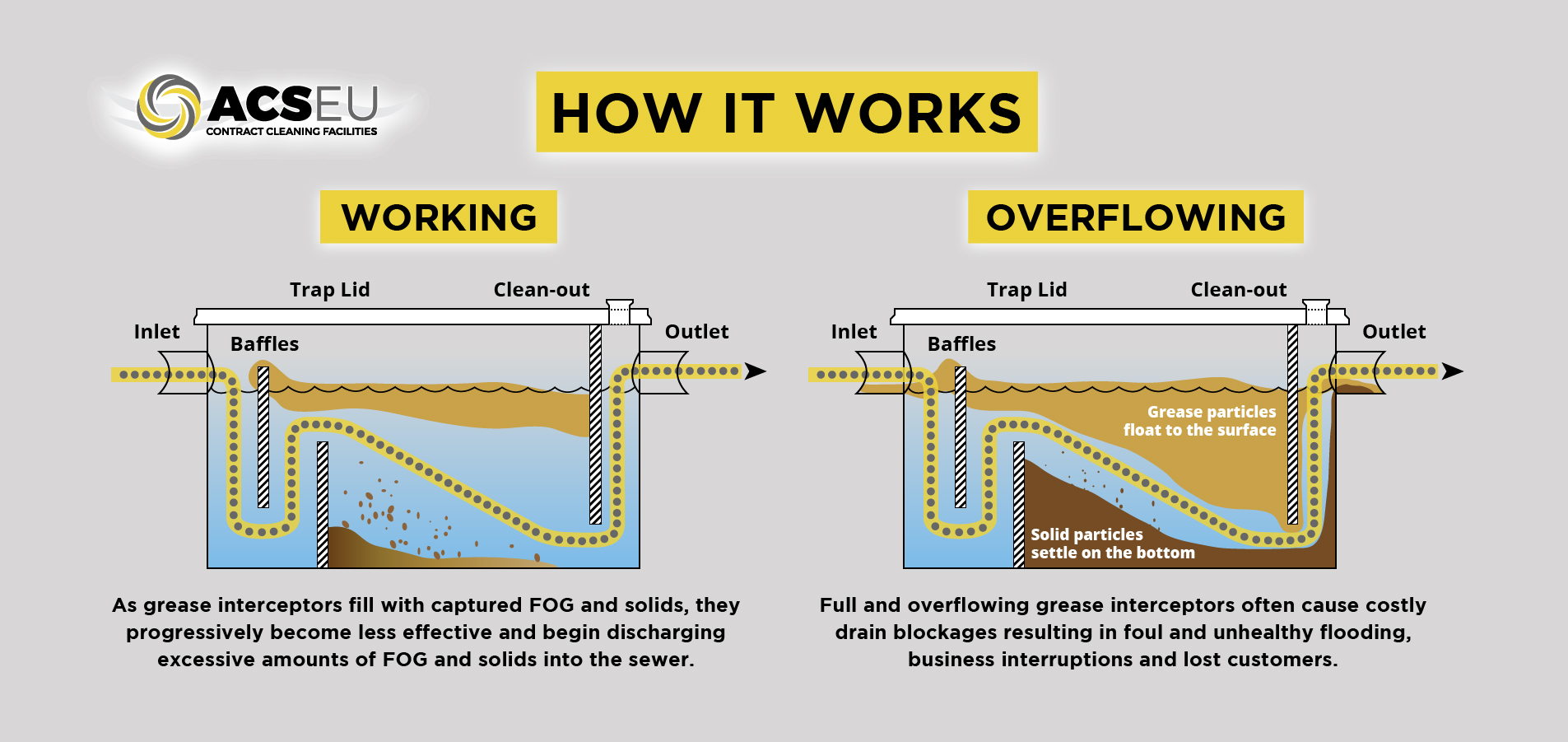

A grease trap (also known as a grease interceptor) is a containment device that captures fats, oils, and grease before they reach the main sewer.

Protecting Kitchens, Compliance, and the Environment

The principle of a grease trap is simple but effective:

- FOG is lighter than water and naturally floats to the surface.

- Heavier solids settle at the bottom.

- Baffles inside the trap slow the wastewater flow, allowing separation to occur.

The result is cleaner water leaving the trap and less risk of downstream blockages. Regular inspection and cleaning are essential to keep the system operating efficiently and in compliance with environmental standards.

Types of Grease Management Systems

Different kitchen sizes and layouts require different grease management solutions. Each option has unique advantages, maintenance needs, and installation requirements.

Passive or Manual Grease Traps

The most traditional and cost-effective solution, passive grease traps use gravity and internal chambers to separate grease from wastewater. They are compact, require no power supply, and are easy to install under sinks or in plant areas.

However, manual traps demand frequent cleaning to prevent build-up and odours. For most smalls to medium kitchens, they remain a compliant and practical choice when regularly serviced.

Automatic Grease Removal Units (GRUs)

Automatic systems take grease management a step further by using heating elements and skimming mechanisms to remove grease into a separate container. Models feature real-time monitoring and visible FOG levels, reducing maintenance downtime.

While they involve a higher initial cost, GRUs offer lower long-term servicing requirements and are ideal for busy kitchens where disruption needs to be minimal. Low-profile designs are available for use under combi ovens or in tight spaces.

Gravity Grease Separators

Installed outdoors or below ground, gravity separators are used for large-scale or high-flow operations, such as hotels, food processors, and institutional kitchens. They use extended retention time to achieve adequate separation and are emptied by licensed waste contractors at scheduled intervals as part of routine maintenance.

Bio-Dosing Systems

Bio-dosing units complement grease traps rather than replace them. Using natural bacteria, they break down FOG within drain lines and inside the trap, reducing the frequency of cleaning. They are an excellent secondary measure for kitchens wanting to maximise sustainability and minimise manual servicing.

Who Needs a Grease Trap?

UK legislation requires any commercial premises that prepare or serve hot food to install an effective grease management system. This includes:

- Restaurants, cafés, and takeaways

- Pubs, bars, and hotels

- Schools, hospitals, and care homes

- Food manufacturing or catering facilities.

In fact, any site producing cooking fats, oils or grease on a commercial scale should have a compliant grease separator installed.

Regulations and Legal Responsibilities

Failing to control FOG is not just a maintenance issue; it is a regulatory issue.

Key legislation includes:

- Building Regulations Part H (Drainage & Waste Disposal) – Requires commercial hot-food premises to fit grease separators meeting EN 1825-1/2 standards.

- Water Industry Act 1991 (Section 111) – Makes it a criminal offence to discharge substances likely to block or restrict sewers, including FOG.

- Environmental Protection Act 1990 (Duty of Care) – Businesses must ensure proper handling, storage, and disposal of waste oils and fats.

- BS EN 1825 Standard – Defines design and performance requirements for grease separators.

Non-compliance can result in fines, prosecution, and reputational damage. In one recent case, a restaurant received a fine for repeatedly blocking the local sewer due to inadequate grease management — a costly reminder that prevention is far cheaper than remediation.

Choosing the Right Grease Management System

Selecting the right grease trap depends on your kitchen layout, capacity, and water authority requirements. Key considerations include:

- Installation location: indoor under-sink, outdoor or underground.

- Size and flow rate: based on the number of sinks and wastewater volume.

- Maintenance access: Traps should be located for easy cleaning.

- Equipment clearance: low-profile GRUs are ideal where vertical removal is difficult.

- Local authority guidance: different authorities specify minimum capacities for specific cuisines or cooking methods (e.g. wok cooking).

- Lifetime cost: balance the initial investment against ongoing servicing, waste disposal, and part replacement.

Working with a professional service provider such as ACSEU Ltd ensures your system is correctly specified, installed and maintained in line with both regulations and manufacturer recommendations.

Matching Grease Traps to Different Types of Kitchen Equipment

Every commercial kitchen has its own mix of appliances, and each produces FOG in different quantities and forms. Selecting the proper grease trap setup is not only about the overall kitchen size — it is also about how your equipment drains, what it discharges, and where it is located.

Fryers and Vats

Deep-fat fryers and cooking vats produce the highest concentration of used oils and fats.

Wastewater from fryer cleaning or oil transfer should be filtered through a high-capacity or gravity grease separator, as these systems handle large FOG volumes more effectively.

Where space allows, positioning a resolute interceptor near the fryer wash-down area helps capture oils before they reach the main line. Pairing with a bio-dosing system further reduces residual FOG build-up in connecting pipes.

Grills, Ovens, and Combi Ovens

Grills and combination ovens produce vapourised grease that condenses during cleaning or when employees rinse drip trays.

A low-profile automatic grease removal unit (GRU) works best in these situations — especially where the trap must sit beneath low-clearance equipment. GRUs skim off grease into a separate, sealed container, avoiding manual cleanouts in tight spaces.

Where frequent wash-down of kitchen surfaces is necessary, a stainless-steel indoor trap with heat resistance ensures durability and hygiene.

Dishwashers and Sink Stations

Sinks and dishwashers carry a steady mix of food particles, oils, and detergents.

A hydromechanical or manual under-sink trap is ideal in this situation, as it slows water flow and separates lighter grease from heavier solids. To maintain proper flow efficiency, the trap size should be based on the sink’s volume and expected flow rate, calculated in gallons per minute (GPM).

For multi-sink setups, link water outlets to a single centralised trap or upgrade to an automatic unit for continuous operation.

Floor Drains and Wash-Down Areas

Floor drains in food prep areas and wash bays can carry a mixture of grease, debris, and cleaning chemicals. These food wastes should then drain into a gravity grease separator or outdoor interceptor, especially where large volumes of wastewater flow.

Installing pre-filtration baskets or strainers upstream of the trap helps prevent solids from entering the system and extends cleaning intervals.

Choosing a grease management system based on your exact equipment layout ensures:

- Full compliance with local water authority discharge limits

- Reduced risk of overflow or odour.

- Easier cleaning access for staff

- Lower long-term maintenance costs

For expert guidance on grease trap sizing and equipment compatibility, ACSEU Ltd provides professional surveys and installations tailored to your kitchen’s unique workflow and appliance setup.

Maintenance and Cleaning

No matter the type of system, regular maintenance is essential. The general rule of thumb is that when the grease and solids combined occupy more than 25% of the trap’s capacity, it is time to clean.

For smaller passive traps, this may mean emptying every 2–4 weeks; for larger systems, intervals can extend depending on usage and bio-dosing support. Automatic traps simplify the process by collecting grease in a detachable container for safe disposal, without interrupting service.

Keeping a maintenance log not only helps schedule cleans but also demonstrates compliance during inspections from water authorities.

Common warning signs that cleaning is overdue include:

- Slow-draining sinks

- Persistent kitchen odours

- Visible grease accumulation

Ignoring these signs can lead to complete system failure and potentially severe plumbing or environmental consequences.

Environmental Impact of Poor Grease Management

The UK’s sewer network faces an estimated 500,000 tonnes of FOG entering drains each year. When mixed with wipes and debris, this forms massive “fatbergs” that block sewers, cause overflows, and cost millions in repairs.

By intercepting and properly disposing of FOG, food businesses directly contribute to reducing pollution, protecting aquatic ecosystems, and supporting national sustainability goals.

Partnering with a Professional

Whether you are installing a new system or upgrading an existing one, professional support ensures reliable, straightforward grease management.

ACSEU Ltd provides nationwide services in grease trap cleaning and maintenance, kitchen extraction cleaning, and catering oil removal — helping commercial kitchens stay safe, compliant, and environmentally responsible.

Grease traps might not be glamorous, but they are one of the most important defences your kitchen has against downtime, fines, and environmental harm.

With the right system, regular servicing and expert guidance, grease management can be simple, sustainable, and worry-free.