Gary Nicholls, MD and founder

Swiftclean and Swift Fire Compliance

Ongoing professional development – essential in the evolving ventilation industry

The ventilation industry plays a critical role in maintaining safe, healthy environments in buildings. Gary Nicholls, MD and founder of Swiftclean and Swift Fire Compliance – and co-author of both TR19 Air and TR19 Grease and their predecessors – says ongoing training is critical in an evolving sector.

As technologies advance and regulations tighten, the expectations placed on engineers and contractors continue to grow. It’s no longer enough to complete a training course and consider the job done – a formal qualification and ongoing professional development are vital.

Regulations Are Evolving – So Should We

At one time, it was acceptable for almost anyone to set up as a ventilation ductwork cleaner; not so now.

Specifications and guidance such as TR19 and DW145 are not static. TR19 has evolved significantly over the years to address hygiene and safety in ventilation systems, and DW145 is now following a similar path, particularly in relation to fire damper installation and ongoing inspection and testing.

These updates reflect a broader industry shift: a positive change towards professionalism, excellence, as well as greater compliance and safety. Fire dampers are a vital, potentially lifesaving safety measure, the maintenance of which should be undertaken by highly competent expert service providers.

These professionals should be well versed with both DW145 and TR19 Air.

Whilst there is still a place for continuous on-the-job training and the acquisition of practical experience, there should also now be formal training with a recognised qualification to ensure competence and professionalism on every project.

DW145 is the Building Engineering Services Association (BESA) industry guidance document for the installation, testing, and maintenance of fire and smoke dampers. It provides a benchmark for good practice in the design, installation, and upkeep of these critical fire safety components, ensuring compliance with building regulations and highlighting the importance of accessibility for future maintenance and testing.

It includes the legal obligation to ensure that fire safety systems comply with the Regulatory Reform (Fire Safety) Order 2005 for England and Wales and the Fire Safety (Scotland) Regulations 2006. With the addition of training courses to instil the knowledge needed to correctly install or to function test and maintain fire and smoke dampers, we can start to expect higher levels of professionalism.

Training That Reflects Real World Challenges

When it comes to training formats, there’s no one-size-fits-all. Online modules offer flexibility, on-the-job training provides context, but practical training centres offer something unique: controlled environments where students can safely learn and practice.

Custom-built facilities allow for:

- Full accessibility – unlike real-world ductwork, which may be at height.

- Clear visibility of potential issues – helping students understand what to look for and how to respond.

- Hands-on experience – which is often more effective than theoretical learning alone.

This kind of immersive training is especially important when dealing with fire safety systems, where the margin for error is minimal.

Whilst it is important that candidates know the theory, and this can be accessed via an online module, immersion in practical training is essential.

As Swiftclean Training Manager, Richard Crews says: “Trainers need to be hands-on with practical training modules, ensuring that every candidate has grasped the practical, as well as the theory.

Everyone should have access to ongoing training; Standards are changing; we need ongoing professional development in our industry to keep pace with all the changes.”

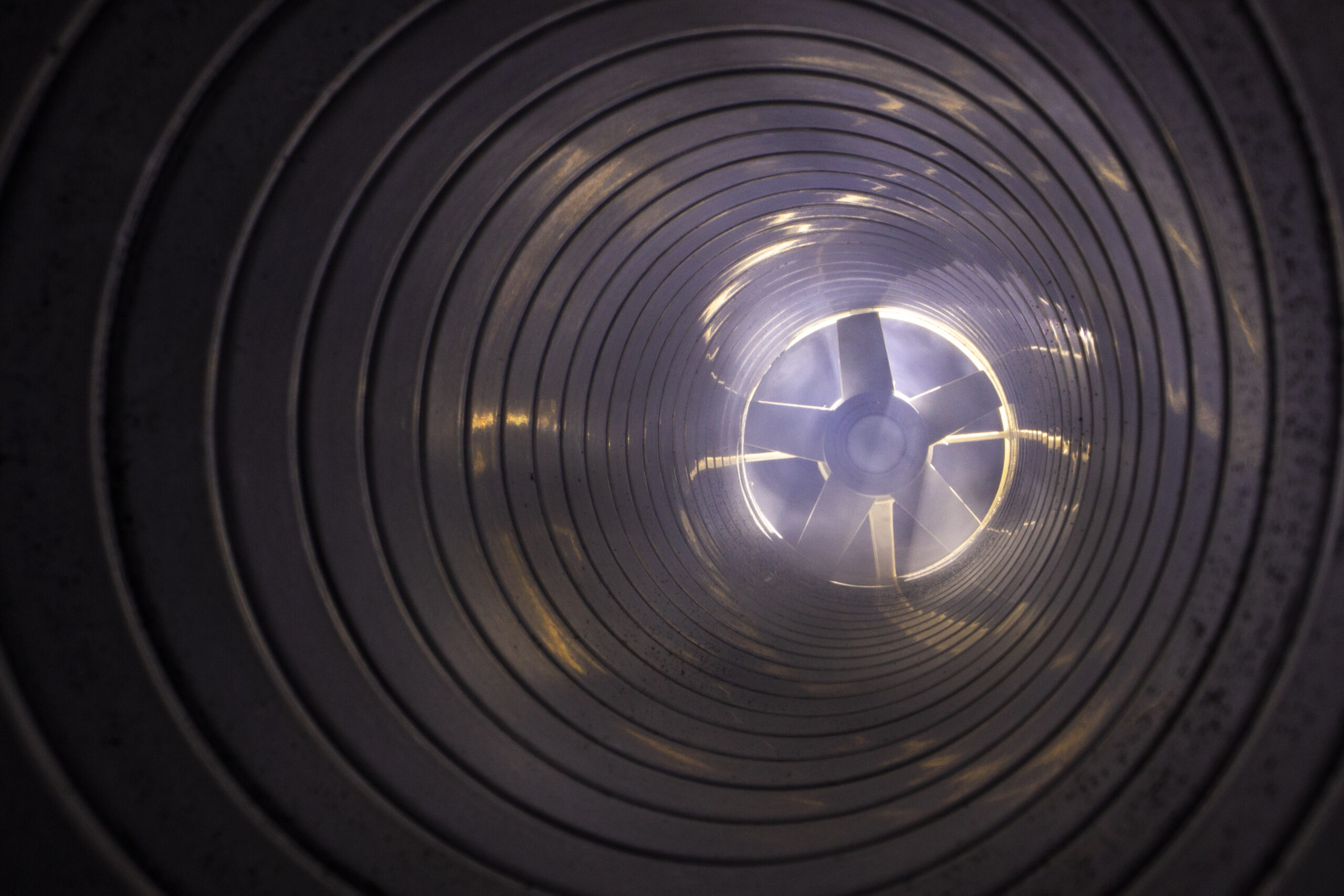

Photo: Fire Damper Training

Time for a Fire Damper Register

The next logical step is a Fire Damper Register, whose members should be committed to training and ongoing professional development. There are precedents for this.

BESA already has a Ventilation Hygiene Register which is managed by its certification arm, BESCA. The Vent Hygiene Register (VHR) was established in 2019 to allow approved members to demonstrate that the specialist vent hygiene works carried out by them to ventilation systems, was done so in compliance with TR19 specification.

We agree wholeheartedly that this is needed, as evidenced by high profile cases such as the Mace versus Mitie dispute over the flawed installation of 132 fire dampers, for which Mace is now claiming £5m in compensation.

Perhaps the most shocking thing about this case is that the fire dampers in question were installed in 2017. It can only have been at a subsequent inspection and test that the plethora of faults in the installation were discovered.

Not only must fire damper installers be competent and professional, but we must also be able rely on the expertise of those who inspect, function test and maintain fire dampers to identify and rectify problems, safeguarding the building’s users. A register would indeed be timely.

DW145: Raising the Bar for Fire Safety

DW145 has introduced heightened inspection requirements, particularly around fire dampers and compartmentation. A simple record of damper testing is no longer sufficient.

The new standards demand a deeper understanding of fire barriers and the integrity of compartmentation – because what good is a compliant damper if the surrounding fire wall is non-compliant?

Key Changes:

- Installation must be documented with photos at each stage.

- Fire stopping around dampers is more strictly enforced due to common compartmentation breaches

- Fire dampers must be easily accessible for testing, maintenance, and repairs. If access is limited, it must be improved or relocated.

- Expectations for damper installation and maintenance are being standardised.

- Legal responsibilities are now clearer. To meet these demands, BESA is working with its accredited training centres across the UK to develop structured training schemes that address the skill gaps. This collaboration is vital to ensure engineers are equipped to deliver work that is not only compliant but genuinely safe.

Compliance: Easier Said Than Done?

Achieving full compliance is relatively straightforward in new builds, where documentation is available from day one. But older buildings present a different challenge. Missing manufacturer specifications, absent fire schedules, and incomplete drawings can make it difficult to assess and maintain safety standards.

In these cases, experienced professionals can guide clients through the journey to compliance – identifying gaps, recommending solutions, compiling a full list of assets for use in future maintenance and compliance – and helping to build a safer environment step by step.

The Role of Property Owners and Managers

We will also need greater awareness among our clients of the importance of competently delivered fire damper services. A Fire Damper Register would certainly help to fast track this; but in the meantime, property owners and managers can also help. When appointing a contractor, ask about their training. Are they up to date with DW145? Do they understand the latest fire safety protocols?

These questions aren’t just about ticking boxes, they’re about ensuring the safety of buildings and the people within them.

Conclusion

The ventilation industry is evolving, and so must we. Ongoing professional development is no longer optional – it’s essential. By embracing structured training, staying informed about regulatory changes, and demanding high standards from ourselves and others, we can move the industry forward – away from ‘hit-and-miss’ uncertainty and toward excellence.