Peter Wolff, Global Manager Ecosystems & Performance Upgrades

Armstrong Fluid Technology

A system approach to HVAC optimisation – from design to operation

Peter Wolff, Global Manager Ecosystems & Performance Upgrades for Armstrong Fluid Technology explains why we need a big picture approach to system performance.

The HVAC sector has long since transitioned from fixed-speed operation to variable-speed control and is now entering a phase defined by data-driven performance management.

Intelligent control methodologies incorporating artificial intelligence and machine learning enable systems to adjust dynamically to changing load conditions and operational requirements.

These advances mean that achieving optimum efficiency requires a holistic approach to system performance, rather than the selection of high-efficiency components in isolation. Big picture control logic and integration must be considered as part of the overall design intent.

By employing open communication frameworks, modern platforms can integrate equipment and control devices from multiple manufacturers within a common environment. These systems utilise performance mapping, analytics, and lifecycle data to maintain operational alignment with design performance over time. Continuous optimisation mitigates performance drift, enhances reliability, and provides real-time diagnostic insight into system efficiency and potential mechanical faults.

The design phase

The path to system optimisation begins in the design phase, determined by equipment selection and control strategies. In this stage, it’s easy to fall into a drag-and-drop style commissioning methodology of picking the most efficient equipment in isolation without considering how these components communicate with the BMS or other nearby hardware.

This can lead to performance gaps from the start, and performance drift over time, estimated to be around 10-30% without regular recommissioning in just two years.

By utilising computer-aided analytics and tools such as digital twinning, it’s possible to get a much better view of the historical and real-time system performance. Advances in computation power, better integration with building models and enhanced predictive analytics have changed the game in terms of hydronic simulation tools. Using them to their full advantage is an absolute must to maintain optimised system performance.

This isn’t to say choice of equipment isn’t of paramount importance. IE5 motor technology in pumps is responsible for massive savings in operation compared to older technology. Today’s intelligent HVAC pumps also have a crucial role to play during the design phase itself, due to their embedded connectivity. These latest generation pump models can track and collect data with greater accuracy than traditional flow meters.

Engineers are already becoming accustomed to the embedded software incorporated in these pumps, and many sites are now routinely harnessing the monitoring and reporting capabilities of these latest-generation pumps to optimise performance after installation.

So why not harness the pump’s advanced monitoring and reporting capabilities to collect the data required for designing the new system, instead of using flow meters? By approaching an energy upgrade in phases and installing the new pumps ahead of the rest of the project, the pumps themselves can supply the necessary data. Most importantly, building owners and occupiers can start to save energy from day one of the initial installation.

The building and load-specific information obtained via the pump software identifies opportunities for system optimisation with high cost/benefit ratios. This helps inform accurate product sizing and selection of other key equipment. It also supports system design for the broader upgrade project, whilst actual, measurable energy savings are demonstrated in real time, throughout this process.

Breaking the project down into smaller sub-projects improves cash flow, and the business case begins to write itself. Depending on the system and load profiles, total energy savings of up to 40% are possible via this approach. Using the data and digital twin technology, the system can be digitally modelled and potential savings demonstrated to provide the business case for stakeholders.

Driving system optimisation

It is estimated that HVAC systems account for around 40 % of the total energy consumption in commercial buildings, with pumps, fans and distribution networks representing a significant subset of that usage1. Once the equipment is selected and commissioned, the way that pumps and other system components are staged becomes critical to achieving system‑wide efficiency.

When a variable frequency drive (VFD) is added to a compressor, pump or fan to improve part-load efficiency, the energy saving potential is huge due to the pump fan laws which state that power is proportional to rotary speed cubed (PαN3).

This would equate to a potential 400% increase in operating efficiencies. However, this is only possible if the pump fan law relationship between pressure and rotary speed, along the natural pump curve, is maintained at the decreased speed.

Traditional control practices often fail to optimise this potential. Pumps, for example, are often set to maintain a fixed differential pressure. This means the pump will not have the freedom to operate along its natural curve and will consume more energy.

Best practice is to utilise advanced integrated control across the system. In the case of variable speed chillers, integrated control ensures operation along the chiller’s natural curve for all operating scenarios, ensuring optimum efficiency at all loads.

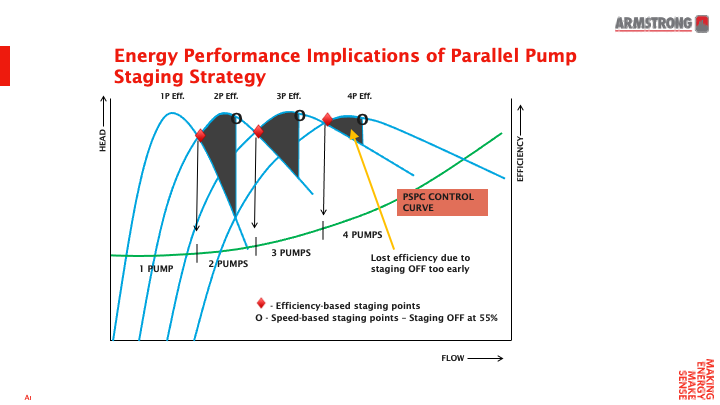

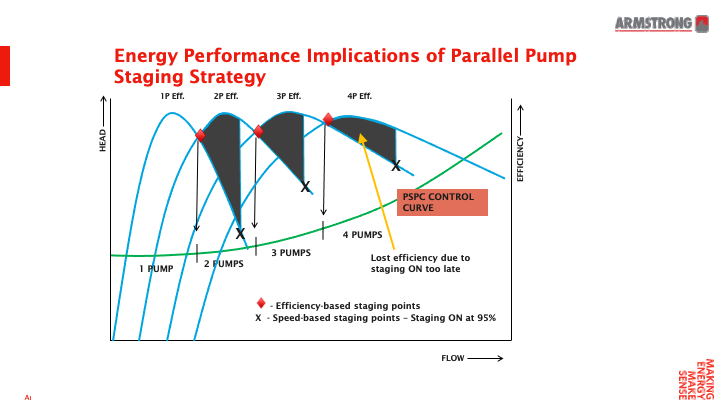

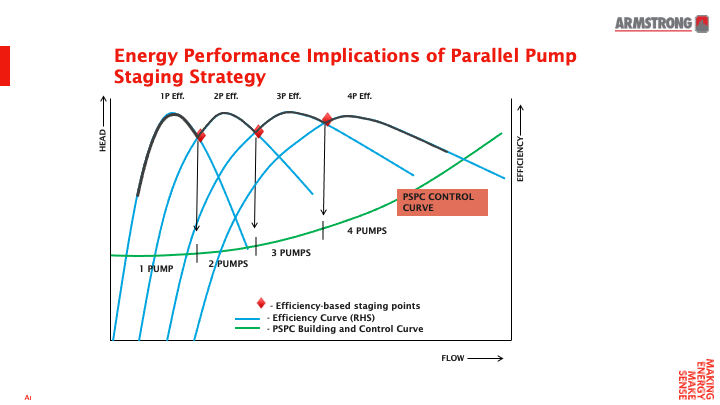

Another important design principle is the employment of demand-based sequencing. Traditional pump staging strategies turn on the next pump when the existing or current pumps reach 95% of maximum speed. Pumps are typically staged-off when the existing or current pumps slow down to 55% of maximum speed. Both scenarios (staging pumps on too late, and off too early) involve lost efficiency (see Figures A and B)

In contrast, efficiency staging control strategies developed by Armstrong Fluid Technology enable systems to “surf” across the top of the efficiency curves throughout the day, eliminating the wastage inherent in pump speed-based control approaches (see Figure C). This improved strategy can achieve energy savings of over 30%.

One example of a holistic approach that harnesses today’s technology is Armstrong’s Envelope platform, which comprises several layers of equipment and digital system capability. At the centre is Envelope Core, the live-data engine that tracks equipment metrics in real time, flags deviations from expected behaviour, and provides actionable insights. Above it sits Envelope Advisor, a building- and portfolio-level auditing layer that uses standards (such as ASHRAE Guideline 36) to benchmark performance and recommend corrective actions. The top layer, Envelope Optimiser, delivers cloud-based analytics, dashboards, and lifecycle services, enabling continuous optimisation of the entire plant.

Achieving sustained efficiency and reliability depends on coordinated monitoring, analytics, and ongoing optimisation of the entire plant, air and water side and this is where an integrated digital performance platform becomes essential.

Reference

1.https://pmc.ncbi.nlm.nih.gov/articles/PMC8776175

Sustainability of Heating, Ventilation and Air‑Conditioning (HVAC) Systems” (N. Asim et al., 2022)