James Cooper, Renewables Manager

Lochinvar

Selecting 2-pipe or 4-pipe heat pump systems for optimal performance

Selecting 2-pipe or 4-pipe heat pump systems for optimal performance

Heat pumps are divided into 2-pipe and 4-pipe systems. James Cooper, Renewables Manager at Lochinvar explains the difference between the two and why installers should select the right technology for their projects.

A 2-pipe system heat pump can be summarised as one circuit with two functions: Heating or cooling. With a 2-pipe system, a heat pump can heat and cool, but not simultaneously.

The delivery circuit is either supplied with heated water for space heating or domestic hot water (DHW). Alternatively, it is supplied with cooled water for space cooling. A 2-pipe air source heat pump (ASHP) is optimised for the delivery of DHW and low temperature hot water (LTHW) for a heating system.

A 4-pipe system heat pump by comparison is made up of independent circuits. It can deliver heating and cooling at the same time. With a 4-pipe system, it is possible to heat or cool separately, or to cool and heat simultaneously. A 4-pipe ASHP is typically optimised for LTHW and heat recovery from any cooling process.

In the 4-pipe system two sub-systems can be distinguished:

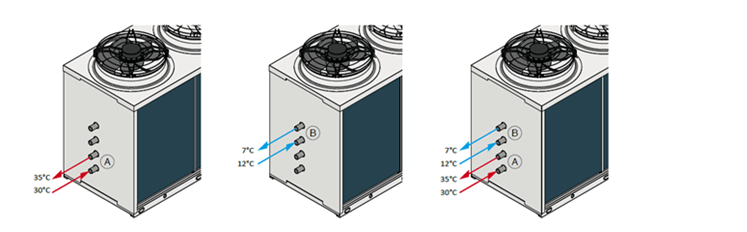

System 1: Heating and Cooling

The heat pump is equipped with a chilled (CHW) side and a warm (LTHW) side that can be controlled independently of each other. The device has four connections for this, two for hot water and two for cold water. There are two plate exchangers: one for hot and one for cold water. This means that the devices can heat or cool, or heat and cool simultaneously. The latter option provides the best operating efficiencies because the system can use heat recovery.

With this approach, there are 3 operating states:

Heating: The appliance functions as a normal air/water heat pump and uses the finned heat exchanger on the source side and the plate exchanger of circuit A on the output side.

Cooling: The unit functions as a normal air/water chiller and uses the fin heat exchanger on the source side and the plate exchanger of circuit B on the discharge side.

Simultaneous Cooling and Heating: The appliance behaves as a water/water heat pump and uses the plate exchanger for heating circuit A and the plate exchanger for cooling circuit B.

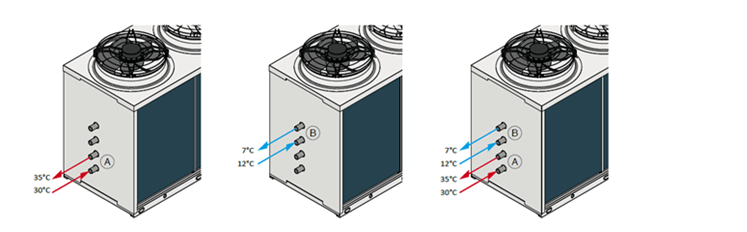

System 2: Heating, Cooling & DHW

System 1 is not suitable for producing DHW. The alternative approach is System 2 where the heat pump is equipped with one side for heating or cooling and one for DHW. This device also has four connections, but now two for space heating or cooling and two for Domestic Hot Water. Either a hot side and a cold side that can be controlled independently of each other.

This system also has two heat exchangers. One for DHW and one for chilled water (CHW). This means that the appliances can either heat or cool, or, for the best possible efficiency, simultaneously heat and cool tap water DHW. The best possible efficiency is achieved because there is recovery when simultaneously operating tap water and cooling.

The plate exchanger for domestic hot water is optimised for the higher set value in domestic hot water operation.

P4S ASHP’s have 4 operating states:

Space Heating: The unit functions as a normal air/water heat pump and uses the finned heat exchanger on the source side and the plate exchanger of circuit A on the output side.

Space Cooling: The unit functions as a normal air/water chiller and uses the fin heat exchanger on the source side and the plate exchanger of circuit A on the discharge side.

Domestic Hot Water Operation: The appliance functions as a normal air/water heat pump and uses the finned heat exchanger on the source side and the plate exchanger B on the delivery side.

Simultaneous Cooling and Domestic Hot Water Operation: The appliance behaves as a water/water heat pump and uses the plate exchanger of circuit A for domestic hot water and the plate exchanger of circuit B for cooling. Essentially providing free domestic hot water via the cooling process.

Selecting the right system

A 2-pipe system is sufficient for heating-only or cooling-only projects. However, for simultaneous heating and cooling, a 4-pipe system is a better option or, as is sometimes done, two 2-pipe systems.

Simultaneous heating and cooling is useful in office buildings that have a north and a south side. If the sun shines all day on the south side, there is a need for cooling, while heating may be required on the north side at the same time. A 4-pipe system is also desirable if there is a requirement for DHW.

When selecting the 4 Pipe system, the potential heat recovery available from the cooling is a key factor. Once the heat recovery base load is known, best practice would be to use 2 Pipe ASHPs and chillers.

To illustrate this with an example, if we consider a building in London, with average climate -3°C Outside Air Temperature (Heating) and 30°C Outside Air Temperature (Cooling).

Heating Load: 300kW, 45°C Flow

Cooling Load: 350kW, 6°C Flow

Proportion of peak heat recovery from the cooling process: 25% or 75kW

We could now select a suitable 4 Pipe ASHP that can meet the peak demand of 75kW heat recovery from the cooling process.

The next step is to select suitable 2 pipe ASHPs and Chillers to match the rest of the heating and cooling load

Heating: 300kW minus the capacity of the 4 Pipe ASHP in heating only mode; 65kW, -3°C OAT = 235kW with a SCOP of 3.5

Cooling: 350kW minus the capacity of 4 Pipe ASHP in Cooling only mode; 70kW, 30°C OAT = 280kW with a SEER of 4.58

The only missing components in this system are the buffers. These would be sized to 20ltrs per kW / by the number of compressors (two per module) which equals 1000ltrs for the heating and 1000ltrs for the cooling.

Heat pump technology is now at a stage where it can meet the heating, cooling and DHW requirements of most buildings. The role of specifiers and installers is to ensure they understand the benefits of different systems and how to apply them for optimal efficiency and occupant comfort.