Hot Water Heat Pump Cylinders: One answer to improved EPCs

Jack Lakin, Hot Water Product Manager for Atlantic explains how hot water heat pump cylinders offer sustainability benefits to new build high rise developments.

As the UK strives towards its Net Zero goals, it’s important that every avenue of technology is explored to ensure carbon reductions are made across all industries and sectors.

A particular focus has been placed on the way we heat properties in the UK. The Climate Change Committee (CCC) highlighted that the UK will not meet its Net Zero2050 target without near complete decarbonisation of our housing stock, which accounts for a fifth of greenhouse gas emissions in the UK.

It comes as no surprise then that the new build housing market has been challenged to reduce property heat losses and build more energy efficient homes. With the much anticipated Future Homes standard set to be released in 2025, we have seen many developers look towards air source heat pumps (ASHPs) as a way of making properties more efficient and decarbonising housing stocks.

ASHPs typically operate three times more efficiently than gas central heating systems that are found in today’s new-build houses. ASHPs have long been a prevalent technology in the European market, with countries such as France supporting electric heating solutions by utilising nuclear technologies to generate large amounts of low-carbon electricity.

More recently, ASHPs have emerged to have a larger presence in the UK heating market for several reasons. Firstly, the efficiency gains facilitate our Net Zero goals and the UK Government is supporting their uptake as a way to decarbonise residential heating.

Secondly, they’re a viable solution for those dwellings not on the grid and thirdly, early adopters have recognised the technical advances in heat pump technology and have sought to capitalise on these.

What we have yet to capitalise on is the development of the hot water heat pump cylinder (HWHP) shown in Figure 1.

These units offer a perfect solution for high rise apartment block developments and other new build homes which make use of the electricity network to provide heating and hot water to homes.

Often powered by a 230V electrical supply, the HWHPs make use of ASHP technology by placing a compact heat pump unit in the top of a traditional cylinder to provide the dwelling with hot water. The in-built immersion heater serves as a back-up heater when needed, but primarily helps to prevent legionella by taking the water temperature above 62oC for a period of time to fully pasteurise the stored hot water.

In the European heating market, this technology is tried and tested with vast amounts of properties combining electric panel heaters for space heating and siting a HWHP in a utility cupboard to service homeowner hot water demands.

The UK heating market is now starting to see this same configuration being specified, particularly in new sustainable high rise developments. This shift is primarily, due to its A+ ERP rating and high efficiency outperforming direct electric cylinders typically used in this setting .

However, while a smaller compressor, typically 650 Watt and 1.6 kW immersion mean HWHPs lack the raw power output associated with fast reheat times, these units more than hold their own thanks to their onboard human machine interface (HMI) not typically seen on direct electric cylinders.

Some hot water heat pumps such as that pictured in Figure 1 make use of intelligent in-built electronics to optimise install, reheat times and efficiencies. The HMI enables the installer to commission the unit in ‘AUTO’ mode with just a few clicks of a button. That’s when the technology comes into its own and starts to learn hot water usage patterns in the property to create efficiency gains by heating the water accordingly and storing it at a different temperature dependent on the usage requirement.

With these smart innovations, HWHPs can obtain high COPs (Coefficient of Performance) of more than 3.

HWHPs are typically installed in an outside/outside ducting configuration. This means that air is pulled in from outside the thermal envelope of the property, across an evaporator via a ducting run by a small fan.

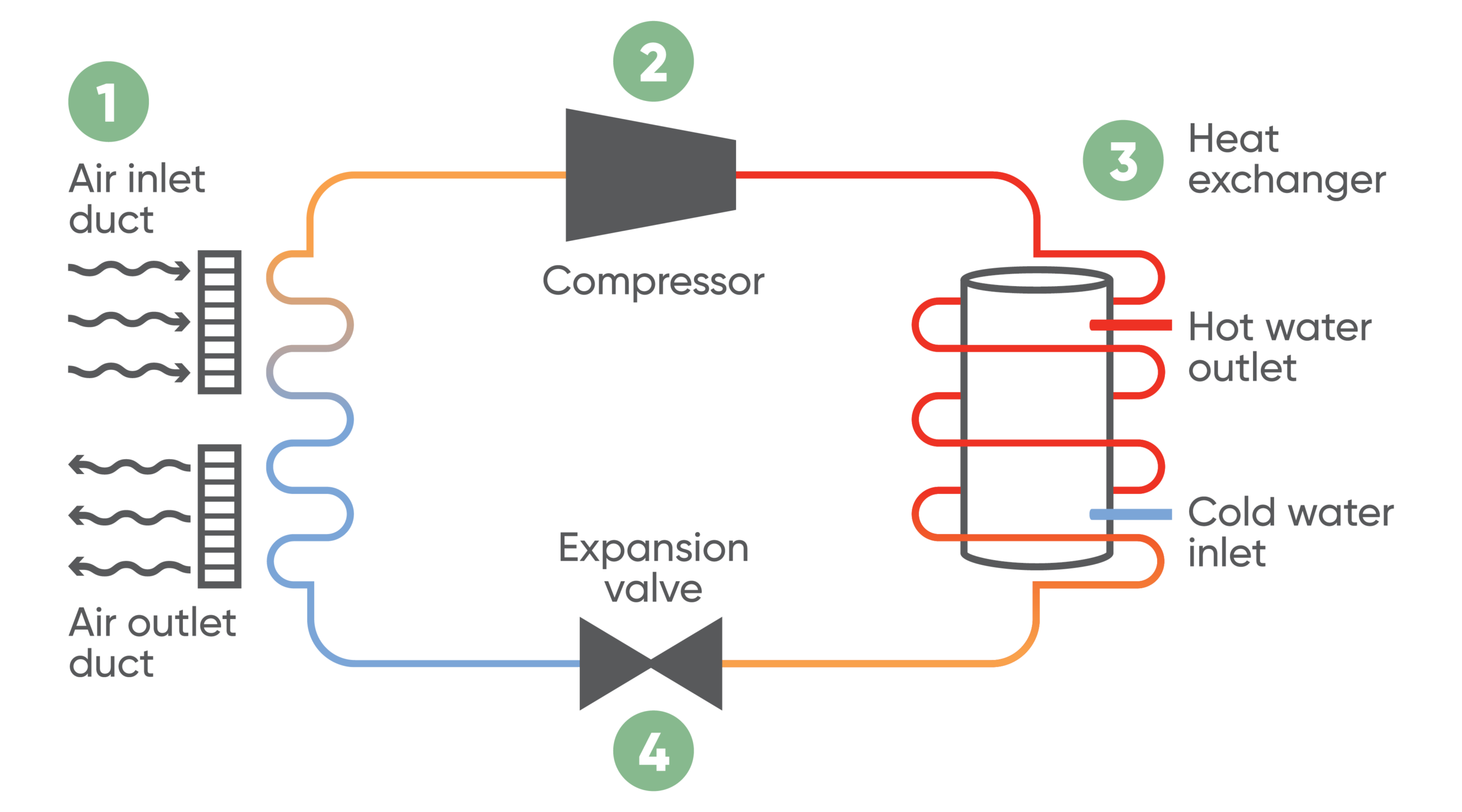

The compact heat pump unit contains a refrigerant which absorbs thermal energy from the outside air due to its low pressure. The compressor then increases the pressure, creating heat. The high-pressure, high temperature refrigerant travels around the coil that sits around the cylinder and transfers the heat to the mains supplied cold water that is now stored in the cylinder, heating it up, ready for use around the home.

Figure 2. below provides visual representation of how this refrigerant cycle operates to deliver hot water in the home. Typically maintaining COPs of 3 or more, HWHPs are around 300% efficient, when compared with gas or direct electric alternatives operating at 90% to 100% efficiency.

The benefit to householders is that HWHPs use three times less energy to generate the same amount of hot water than existing 100% direct electric solutions. This makes running HWPs cost effective, subject to tariff conditions and usage.

It’s this COP figure which features heavily in the calculations of SAP scoring that seeks to reward the most energy efficient homes.

As we strive to decarbonise our housing stock in alignment with the UK’s 2050 Net Zero goals, the hot water heat pump cylinder is one option new build developers can capitalise on to deliver sustainable hot water, improved EPC ratings and, above all else, energy efficient homes.