Gary Nicholls, Managing Director

Swiftclean

Preventing fire in laundries – understanding TR19 Air

BESA’s TR19 Air has raised awareness of the need for ventilation hygiene. But the fire risk posed by infrequently cleaned laundry extract ductwork is still often underestimated, as Gary Nicholls, Managing Director of Swiftclean explains.

Thankfully, due to BESA’s TR19 Air and its forerunners, we have seen a significant rise in awareness of the importance of regular competent cleaning of ventilation ductwork. However, one of the least discussed areas of ventilation hygiene, which still deserves greater awareness, is that of laundry extract ductwork cleaning.

The UK’s commercial laundries together wash, dry and press over 50 million pieces of laundry a week, including more than 90% percent of the NHS’s textile products, as well as 95% percent of linens used by the nation’s hotels. Commercial laundries also handle almost all of the laundering of workwear from food and pharmaceutical factories across the UK. The commercial laundry sector provides more than 24,000 jobs.

It is believed that without the tasks performed by commercial laundries, many parts of the UK economy would be unable to function. The Textile Services Association (TSA) estimates that if commercial laundries suddenly ceased to operate, 90% of hospitals would not be able to operate for more than a single day, and would be forced to close within 24 hours. Hotels, pharmaceutical plants, and food processing factories would all be faced with closure within a few short days. It is certainly not a sector to be underestimated.

The TSA reports that, like other industries, laundries have faced a challenging time, with 55% reporting serious long-term financial challenges, particularly due to the huge rises in energy prices and other cost increases.

Competition is fierce, whilst many clients, such as care homes and hotels, have both specific needs and high expectations. Downtime due to problems with machinery is extremely costly.

Regular maintenance is therefore critical to the smooth running of laundries, in order to avoid equipment breakdowns. This should most definitely include regular laundry extract cleaning.

One of the unavoidable consequences of the commercial laundering of towels, bedding and other textiles, is the generation of large quantities of lint and fibres. These particles become airborne during the drying process and are drawn out of the drier with the hot exhaust air stream.

Lint and fibre will accumulate in drier extract ductwork, forming a serious potential fire risk. Lint, in particular, is highly flammable, especially when deposits are reheated by subsequent use of the drier.

Whereas much of the now standalone TR19 Air specification is concerned with hygiene and indoor air quality, in the case of laundry extract cleaning, it is also a vital fire prevention measure. The building manager or owner also has serious responsibilities under the Regulatory Reform (Fire Safety) Order of 2005 to ensure that they minimise the risk of fire in the premises.

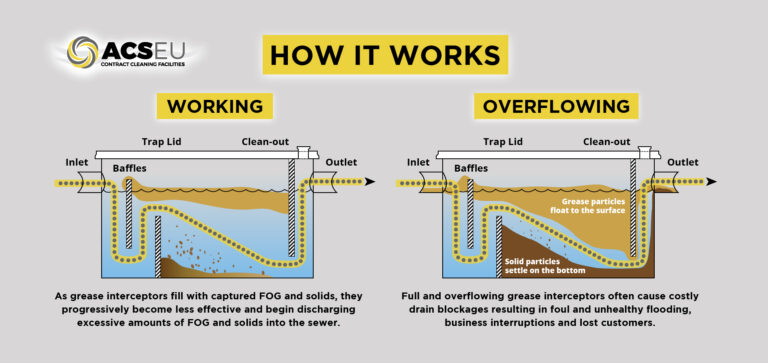

There are several factors which may contribute to the risk of tumble drier fires. One of the main causes is reduced air flow in the tumble drier, due to the accumulation of lint in filters or traps and in the extract ductwork.

Air must be able to flow freely and, if it is not possible to draw in a good supply of cooler, fresher air, the drier drum is prone to overheating. This lack of air slows the drying process, so that each load becomes more costly to dry, and sends overheated air into the extract system. An overheated air stream, in turn, can raise the temperature of highly flammable lint deposits in the extract ductwork to spontaneously combustible levels.

Incorrectly sized or ill-fitted filters also pose a fire risk as they facilitate the collection of lint, fluff and fibre deposits. A blocked filter interrupts the air flow and leads to overheating. It can also lead to deposits collecting in voids within the drier machine itself. Any deposits of this nature should be removed during the regular servicing of the drier machines by the service engineer.

The tumble drier extract system and its associated ductwork, however, fall under the remit of TR19 Air, which requires the regular competent professional cleaning of all ventilation ductwork – laundry extract vents included.

In a commercial laundry, machines are in almost constant use, so it is critical that the ductwork is compliant with TR19 Air.

To achieve compliance with TR19 Air, the specialist cleaning provider should take a thorough, step by step approach, beginning with a thorough visual inspection, assessment of the condition of the ductwork, and measurement of the airflow.

The technician should then gain access to the inside of the ductwork, assuming that access points have been installed. These are required for ongoing compliance, so if they have not been installed, they should be retrofitted – something which our technicians will do at the time – to provide adequate, safe access to the entire system.

All dust, fluff and lint should then be completely removed, using mechanical brushing tools, so that no fibre particles remain on the inner surface of the ductwork.

It is important for the building manager or owner to be able to demonstrate their compliance, particularly for insurance and legal purposes. As a Responsible Person under the Regulatory Reform (Fire Safety) Order 2005, they can be prosecuted for negligence in failing to comply with TR19 Air, especially in the event of a fire which causes risk to life or significant damage to the laundry and any neighbouring property. A conviction can result in a custodial sentence.

In the event of a fire, your insurance company will also want to see evidence of compliance – most will refuse to pay out on a claim without this, and some will refuse to provide insurance cover following a fire where the affected ductwork did not comply with TR19 Air.

You should therefore select a provider that will deliver a full digital report ideally within five working days of completion of the clean. This should include pre and post-clean photographs which can be used as evidence that you are compliant.

You should also choose a specialist cleaner who can ensure that you receive BESCA certification of the clean, which demonstrates your compliance with TR19 Air, as well as with fire and insurance requirements.

Finally, you should ensure that you have in place an ongoing plan of preventative cleaning and maintenance. This helps minimise fire risk for the longer-term future; guards against business interruption; and protects your premises and equipment.

In practice, this means choosing a member of the BESA Vent Hygiene Register (VHR), the UK’s official register for vent and ductwork hygiene contractors, to professionally clean your laundry extract ductwork. VHR membership requires cleaning providers to demonstrate a good track record of compliance and to use properly trained and competent operatives to ensure that cleaning is carried out competently and compliantly every time. Only VHR members can provide BESCA post-clean certification.

TR19 Air helpfully includes tables which set out the intervals at which each different type of ductwork should be professionally cleaned, according to its usage and function. Laundry extract ductwork has always fallen under the scope of the former TR19 and TR17 documents, but we must hope that, with the creation of TR19 Air as a stand-alone specification, the greater authority which this brings will help to raise awareness of this often-neglected discipline, together with greater compliance – and fewer fires.